METCAL hot air gun HCT-910 is newly launched

In the SMT operation process, whether it is machine or manual, it is inevitable that some adverse problems such as solder leakage may occur due to various reasons,

Wrong soldering, virtual soldering, erecting monuments, shifting, reverse pasting, insufficient soldering, etc,

When these problems occur, an electric soldering iron is usually the preferred tool. But more often than not, choosing a more suitable repair tool can ensure the implementation of the repair process,

It can also improve the efficiency of repair, saving operators a lot of unnecessary trouble.

Easy to use, controllable process, can provide comprehensive solutions for various production and repair applications.

1、 Simplify the rework process through an intuitive user interface (UI), making it easy to set up and adjust the system

The repair situation varies, so the hot air tool must include precise and simple temperature and flow rate control.Considering usability during design,

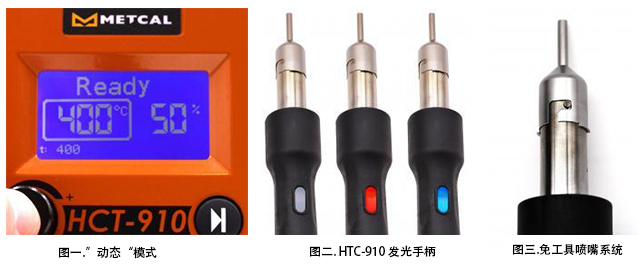

Metka's new HCT-910 hot air repair systemFeaturing a new 'dynamic' manual mode, temperature and airflow can be quickly adjusted through a single knob.

Easily switch between temperature setting and air flow rate, rotate the knob to the desired setting, and then push the knob to adjust.

IIImprove operator safety through clear system status indicator lights

One key to improving productivity and process control is to ensure the safety of operators. To ensure a workplace without harm around potentially hazardous tools,

When the convective system is very hot, it should be as obvious as possible.

On Metcal's HCT-910, the current status of the system is highlighted on the large display screen. This is an excellent way to quickly determine if the heater is engaged.

Even better, the status indicator light of HCT-910 is located exactly on the handle. When the system is in heating mode, the LED on the handle will emit lightRed light.

When the system is in cooling mode, the LED will change toblue. This enables operators and floor managers to quickly assess the status of equipment.

3、 Use tool free nozzle for quick replacement and rework

When switching to different nozzle configurations, operators do not need to waste time searching for screwdrivers to disassemble and adjust. By selecting a hot air nozzle designed specifically for tool free nozzle replacement,

Keep the workflow running smoothly. The Metcal HCT-910 features an improved tool free bayonet system and is backward compatible with traditional HCT-900 nozzles. Just rotate quickly

Unlock the nozzle and easily lift it off the heater tube assembly. The other nozzle can easily slide in and be fixed in place, and quickly rotate in the opposite direction to complete the replacement.