METCAL temperature adjustable induction welding system with small belly and high energy

Manual welding products are mainly divided into two types: adjustable temperature resistance welding systems and fixed temperature induction welding systems.

And now, the third type-Induction welding system with adjustable temperatureIt has appeared.

This new technology is the key to the development of METCAL's patented GT series manual welding system, which combines the advantages of adjustable temperature and induction heating technology,

Improve the welding performance of the product.

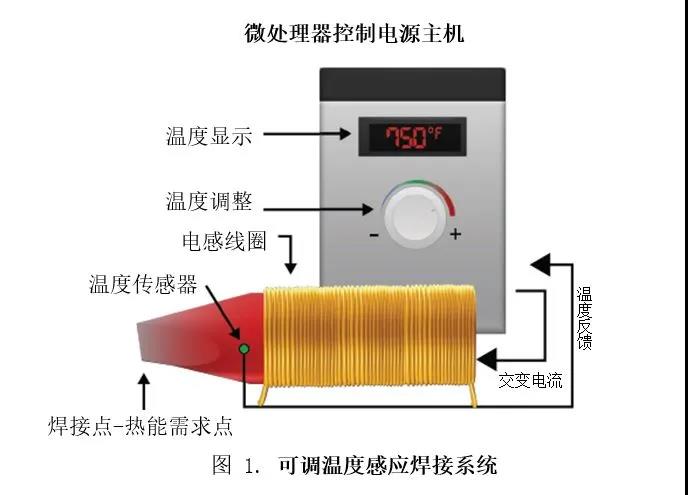

Adjustable temperature sensing welding system

GT Adjustable Temperature Welding System

The METCAL GT welding system mainly includes inductive coils, alloy heating elements, temperature sensors, microcontroller PID feedback to the microprocessor controlled power supply host, and soldering iron tips (Figure 1)

The GT system utilizes induction rapid heating caused by hysteresis and eddy current losses. The design of the system ensures that heating is not limited by the Curie temperature.

The controller adjusts the AC power to a very high frequency (approximately 465 kHz). At these high frequencies, the skin effect limits the skin depth to around 0.002 inches.

This depth has very little resistance to the flow of thermal energy, so heat can flow efficiently in the system.

The METCAL GT series manual welding system controls and manages the temperature of the soldering iron tip through a patented hardware and software system.

The temperature sensor and the proportional integral derivative (PID) feedback loop of the microcontroller work together to achieve continuous modulation temperature control.

The temperature of the soldering iron tip can be precisely controlled by precise management of the alternating current flowing through the heating element to achieve reliable performance.

The GT system allows operators to create preheating and heating curves for soldering iron tips to achieve satisfactory welding results.

The METCAL GT series manual welding system is equipped with various shapes of soldering iron tips. Choosing the appropriate soldering iron tip according to the needs of the welding application is an important component of evaluating system performance.

Temperature adjustable induction welding systemadvantage:

1. Rapid temperature recovery,

2. High thermal performance,

3. No thermal resistance,Efficient,as well asThe temperature is easy to control.

System performance:

GT Adjustable Temperature Welding System

By visually inspecting the heating time, welding time, reheating time, and welding cycle, we can observe that a high-performance welding system can provide efficient welding cycles and consistent weld quality.

The manual welding system depends on the following three factors:

1. Heating technology for welding systems,

2. Selection of soldering iron tips, and

3. Power of the system

While system power has a significant impact on performance, the heating technology used and the selection of the correct soldering iron tip play a more important role in system performance.

When choosing a soldering iron tip, you can feel that the use effect of the integrated soldering iron tip is better than that of the split soldering iron tip, thanks to the fact that the integrated soldering iron tip connects the heating element with the soldering point

Integrated design, the closer the heating element is to the welding point, the faster the welding point naturally heats up.

Due to the inherent differences in thermal resistance and thermal responsiveness, induction heating technology is significantly superior to resistance heating technology. Therefore, induction heating technology is adopted

The overall performance of the METCAL GT series temperature adjustable welding system exceeds that of its peers.