Why use a sleeping iron frame

Release Date:2017-07-27

The lifespan of soldering iron tips has been a topic of discussion for all manual soldering users. Whether you are in production, repair, or research and development, the cost and lifespan of soldering iron tips affect your overall soldering investment. Although operators almost always want to make the soldering iron tip hot, hotter, hotter, using a sleep type soldering iron holder can significantly increase the lifespan of the soldering iron tip.

When the soldering station is not in use and idle, a sleep type soldering iron holder will automatically reduce the heat provided to the soldering iron tip, resulting in:

1. Reduce idle temperature

2. Slow down chemical reactions

3. Formation of fewer metal compounds

4. Less oxidation

5. Increase longer service life

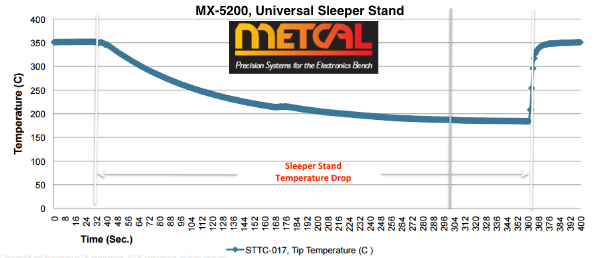

The following chart is a temperature chart using a sleep soldering iron holder

The above chart clearly shows that this greatly reduces power, which also means that a production environment can affect your overall return on investment. Here are some examples to illustrate

For example, if you have 5 soldering iron tips that use an average of 40W per hour during the production process, the power consumption is 5 * 40=200 * 8 (h)=1600W per day. The potential soldering iron tip can take up 50% of the time between operations. If there is a soldering iron rack during sleep, the idle wattage can be reduced to around 5W, and the power consumption becomes 5 * 40=200 * 4h=800 (5 * 5=25 * 4h=200)=1000W per day

In this way, we can save 600W per day, nearly 30%. Fortunately, each MX or MFR series welding station from Metcal comes with a sleeping iron frame.