Techcon Glue Valve Usage Guide

Release Date:2017-04-19

Techcon SystemsWe offer a wide range of dispensing valves, from simple manual dispensing to precision dispensing valves for automation applications. These dispensing valves include:

Disposable material path rubber valve for difficult to handle fluids

Easy to maintain, precise dispensing valve capable of handling various viscosities, fluid pressures, and dispensing sizes

High speed dispensing valve suitable for precision dispensing of materials containing high hardness fillers or high viscosity fillers

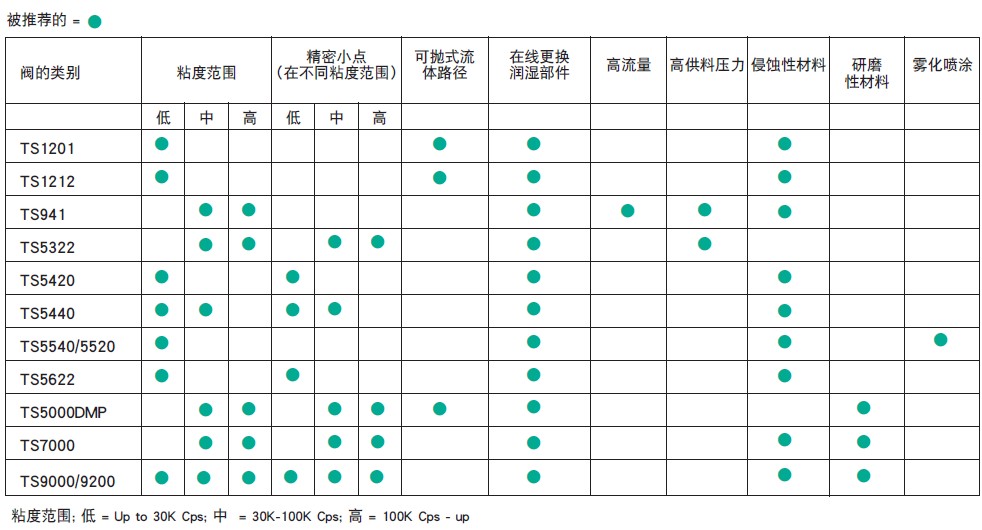

Techcon Systems offers a wide range of adhesive valves to meet every dispensing need. We encourage customers to use the "TECHCON Material Testing Program" for ordinary or unique applications Choose the appropriate dispensing valve. The following table shows the characteristics of different valves.

Clamping valve TS1201/TS1212Low viscosity range, disposable fluid path, can replace wetting parts online, and corrode materials.

High pressure valve TS941From medium to high viscosity range, wetting parts can be replaced online, with high flow rate, high feed pressure, and corrosive materials.

Small spool valve TS5233Viscosity range from medium to high, precision small adhesive dots (different viscosity ranges) from medium to high, can be replaced with wetting parts online, high feeding pressure.

Needle valve TS5420Low viscosity range, precise small adhesive dots (different viscosity ranges) are low, and wetting parts can be replaced online to corrode materials.

Micro needle valve TS5440The annual payment range is low to medium, and the precision small adhesive points (with different viscosity ranges) are low to medium. Wetting parts can be replaced online, erosion materials can be used, and atomization spraying can be applied.

Spray valve TS5540/5520Low viscosity range, capable of online replacement of wetted parts and erosion of materials.

Diaphragm valve TS5622Low viscosity range, precise small adhesive dots (different viscosity ranges) are low, and wetting parts can be replaced online to corrode materials.